- HVAC Controller AM6108B

- IAQ Transmitter AM6108A

- Wall Mount Transmitter AM6208W

- Duct Mount Transmitter AM6208D

- Desktop Air Quality Monitor AM7000

- Mini CO2 Detector CM01

What are you looking for?

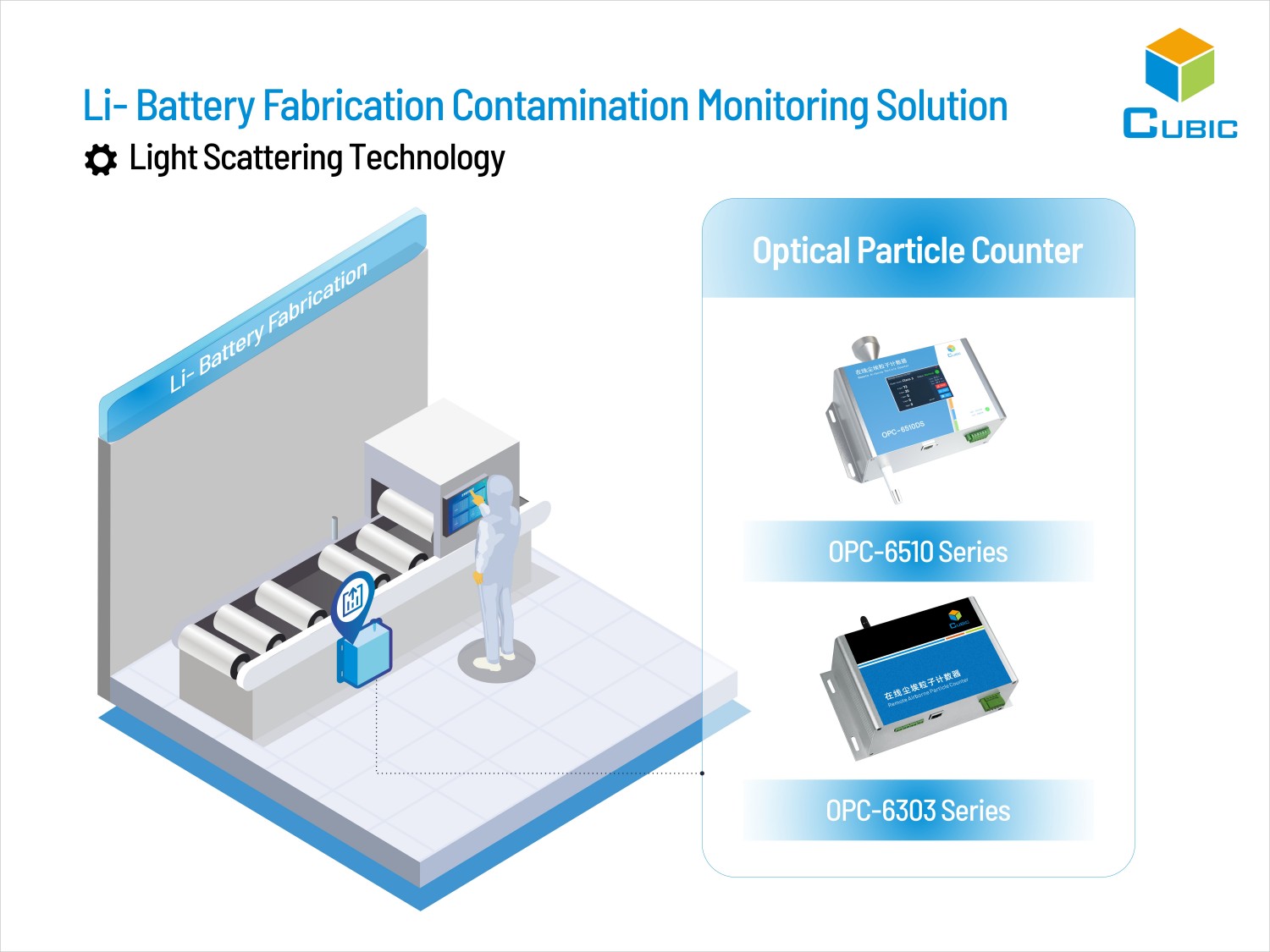

In lithium-ion battery manufacturing, particularly in electrode material preparation and cell assembly processes, controlling airborne particulate contamination is crucial to ensure the performance and reliability of battery products.

Regulatory standards such as ISO 14644 establish criteria for classifying air cleanliness in controlled environments. In the context of EV battery manufacturing, attaining an ISO Class 5 or higher is frequently imperative owing to the susceptibility of battery components to contamination.

To help monitor and control contamination during battery fabrication process, Cubic has designed 2.83LPM Particle Counter OPC-6303 Series and 28.3LPM Particle Counter OPC-6510 Series, based on its core light scattering technology.

The remarkable features of Cubic online optical particle counters:

lOutput particle number in 5 channels/6 channels (0.3μm, 0.5μm,1.0μm, 2.5μm, 5.0μm, 10μm)

lBuilt-in high power industrial grade linear laser, accurate identification

lBuilt-in ultrasonic gas flow sensor, constant and stable flow sampling

lModBus RS485 and MQTT communication protocols available

l24/7 online continuous monitoring

Furthermore, for ensuring the safety during Li-battery manufacturing process, it is essential to take effective measures to prevent electrolyte leakage or thermal runaway.

Cubic has designed NMP gas leakage detector Gasboard-2063 and electrolyte leakage detector AM4210. Gasboard-2063 has the characteristics of fast response, high sensitivity, long life, zero-point self-calibration, and maintenance-free. It also meets the requirements of ExdⅡCT3 explosion-proof certification and meets the application needs of NMP concentration leakage monitoring of lithium battery coating machines. Cubic self-developed handheld electrolyte leakage detector AM4210 is designed with a TFT LCD, which can not only detect leakage points, but also quantitatively analyze the leakage concentration in the current environment and present the current concentration data.